Capture Greater value from System Engineer

Capture Greater value from System Engineer

Introduction:

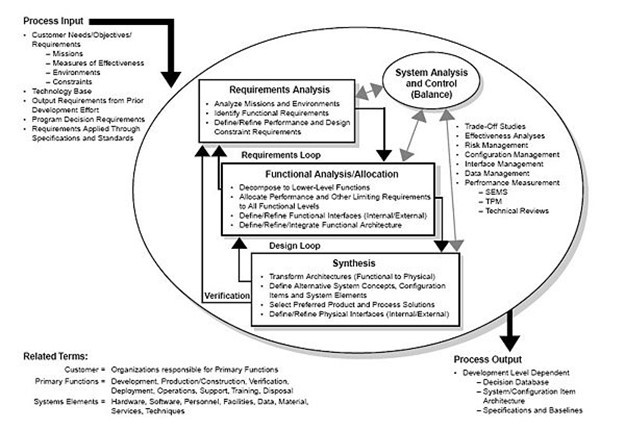

Systems engineering is an interdisciplinary field of engineering and engineering management dealing with the design, integration, and management of complex systems across their life cycles. Systems engineering, at its heart, organizes this body of information using systems thinking concepts. An engineered device, which is the end result of such efforts, can be described as a set of components that work together to perform a useful function.

The systems engineering method is more of a discovery than a manufacturing process. A manufacturing process focuses on repeatable activities that deliver high-quality outputs at a low cost and in a short period of time. The first step in the systems engineering process is to recognize the real concerns that need to be fixed, as well as the most likely or high-impact failures that may occur. Systems engineering then requires seeking solutions to these issues.

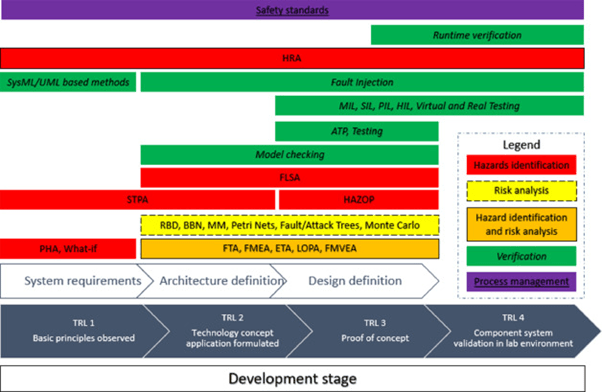

Methods and their applicability to system engineering processes

System Engineering Activities:

From a simple set of project goals, the systems engineering phase includes the top-down creation of a system's functional and physical specifications. The goal is to coordinate information and expertise so that those in charge of preparation, production, and operation of the systems needed to complete the task can do so more efficiently

The importance of systems engineering can be realized in a variety of ways, including:

- Improved ability to predict device life-cycle costs.

- Due to consistent traceability of specifications, design features, and configuration control, increased ability to affect design changes and retrofits.

- Since the whole structure was considered in the implementation process, there was a decreased need for overhaul.

System Engineer processes:

Both innovative, manual, and technological activities required to define the product and to translate a system concept into a sufficiently comprehensive system design specification for product manufacture and implementation are covered by systems engineering processes.

- Stage of implementation

- Stage of conception

- Description of the mission

- Stage of development

Tools are used at different stages of the systems engineering process, depending on their application:

Capture Greater value from System Engineer:

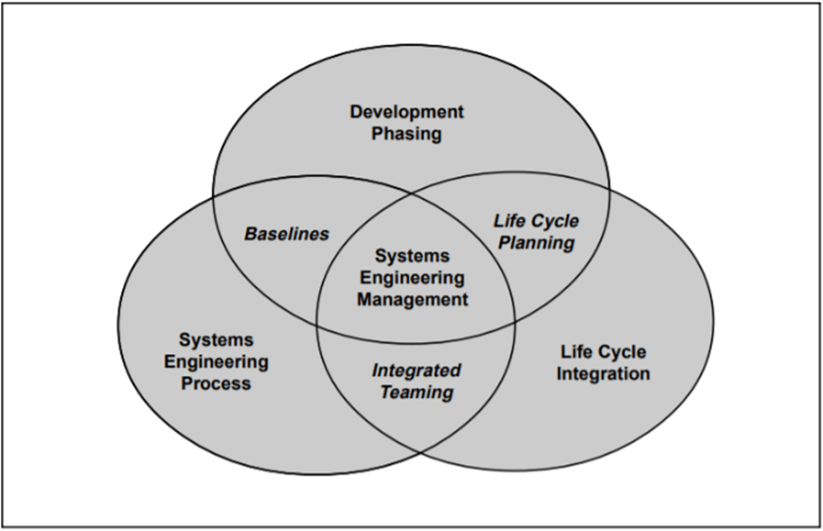

SE governance is the process and practice by which a company establishes the decision rights that enable SE to offer the greatest amount of business value.

Establishing a SE governance model, which should be adapted to the specific context in which the company operates and delivers value, is one of the main implementation steps when a business determines its SE strategy. SE governance provides the structure and accountability for topics including design authority, financing and permits, project initiation and termination, as well as the legal and regulatory environment in which the system will be built and operated. The reasoning and rules for why and how business strategies, procedures, practices, and resources are adapted to the environment are included in governance. Product and process measures, documentation requirements, and technical reviews and audits can all be part of SE governance.

Tools of System Engineer:

1. Need for Good Data:

Although important, creating a mathematical representation that describes a function of a system or a subsystem is rarely enough. If a mathematical representation is based on good data, it can only make quantitative output forecasts. As a result, accurate data on the system's or subsystem's output is also needed.

Of course, the essence of these data varies depending on the issue at hand, but one significant generalization can be made. In a complex system to evaluate the method, you'll need to know the mean and variance of relevant process times, such as the time it takes to produce each process and the percentage of users who need each process.

2. Concurrent Engineering:

Concurrent innovation has been used by manufacturers in a number of industries to design, engineer, and manufacture goods that meet the needs and aspirations of consumers, are defect-free and can be manufactured cost-effectively over the past 20 years. Concurrent engineering is a disciplined approach to breaking down functional and obligation silos, allowing different functional units to understand how their individual skills and efforts can be combined to maximize the system as a whole. This group is then in charge of designing a product or process as a whole.

3. Quality functional Deployment:

QFD is a powerful tool for creating processes and procedures that provide the quality of service that customers want.

References:- https://en.wikipedia.org/wiki/Systems_engineering

- https://www.sebokwiki.org/wiki/Systems_Engineering_Organizational_Strategy

- https://www.nap.edu/read/11378/chapter/5

- https://www.sciencedirect.com/topics/social-sciences/systems-engineering-process