Model Based Testing(MBT) for embedded devices

MBT for Embedded devices

In today's world, finding a smart device without an embedded computer system is virtually impossible. Embedded systems are the main component that separates goods in terms of functionality and functions. This advantage, however, comes at a cost. Designing the architecture, designing the platform with programming languages and tools, integrating processors, peripherals, and applications, and finally checking compliance and functionality are all phases that an embedded device goes through.

As the market for small devices rises, processors and microchips become smaller, necessitating the production of complex control systems. To optimise the overall system design, it is important to track the entire embedded control system and application design processes. The model-based design methodology proves to be an effective and efficient way of understanding component parts such as commercial microcontrollers and processors, as well as algorithms and code for microelectronic and embedded system activity. Via visual prototyping and model simulation, it assists in solving numerous difficulties and complexities that occur during the lifecycle of embedded application software.

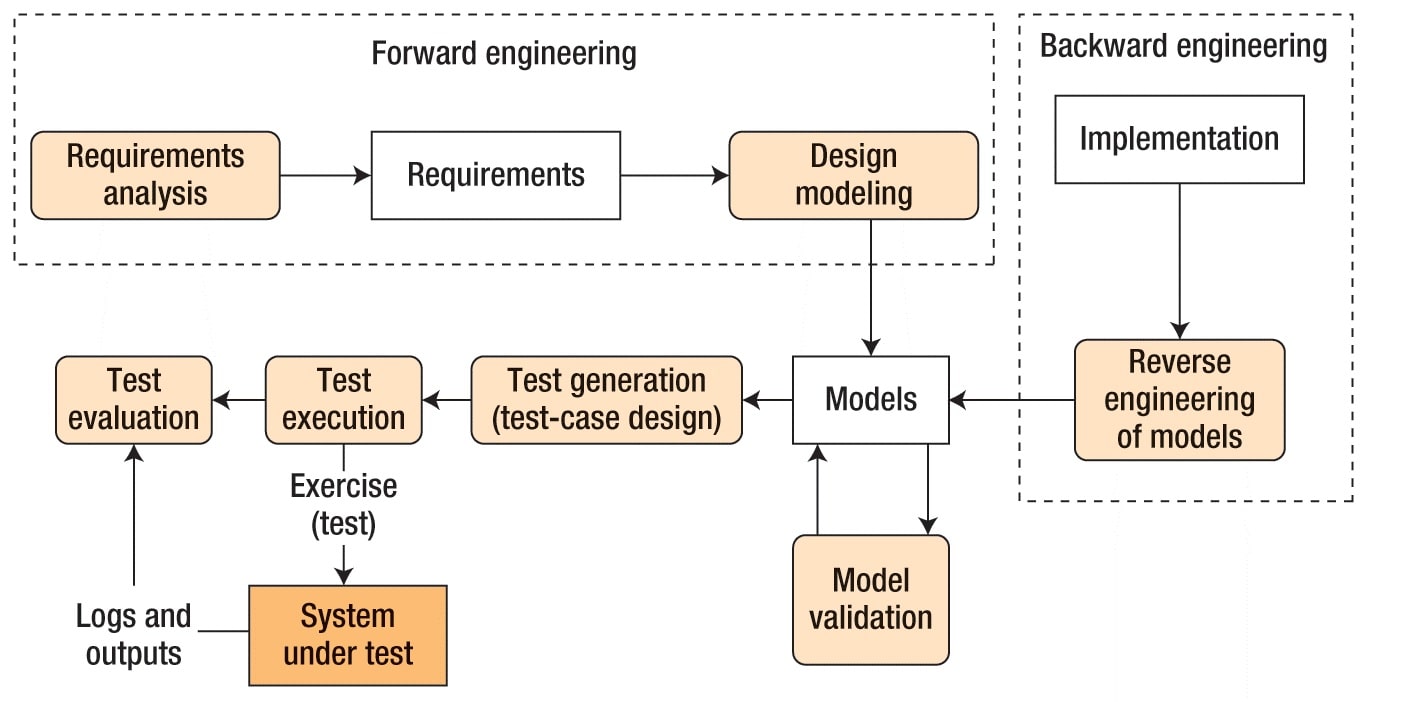

Model-based design (MBD) is a technique for verifying and validating software in a simulation environment. It covers a broad range of disciplines, functional behaviour, and cost/performance optimization in order to deploy a product from the initial concept to final validation and verification testing. While many organisations use modelling in some way, some use simulation on an ad hoc basis, losing out on the possible verification benefits.

Why model base testing?

Design information is traditionally transferred and managed in conventional design processes in the form of text-based documents, which are difficult to comprehend and subject to interpretation bias. Engineers manually generate embedded code and data from text-based documents, which is time-consuming and error-prone.

Modeling, which has always been an integral part of the design process, is the priority for embedded control and algorithm designers. Model-based architecture is a major shift in embedded device design. It allows embedded software developers to differentiate between a simulator and a software development tool, allowing them to construct simulation models and evaluate whether algorithms would work before writing embedded code. System engineers can easily see if the whole system (mechanical, electrical, and embedded software) will operate as expected using virtual prototyping, even before the hardware is manufactured and ready for testing.

Model-based Design's Production Flow:

Functional Modeling: A model defines the different functionalities of embedded device subsystems. It maintains consistency with other methods and processes when defining functions with less iterations and less effort in product creation. It follows an algorithm that specifies the electronic design rules for different process flows and embedded software components.

Implementation Modeling: Using research methods such as simulation and design verification, this method defines the control algorithm, modules, subsystems, and the context in which the embedded device will be used. It aids in the reduction of implementation complexity by improving idea consistency and optimising code. It keeps track of device component interactions, such as timing delays and continuous parameters, and ensures that they are consistent with all embedded systems.

Advantages of the model base testing for the embedded system:

The key advantage of using MBD is that it produces code automatically, which prevents human errors and allows for code reuse. Furthermore, businesses have consistently achieved immediate and concrete results by gradually implementing model-based design, such as:

- Getting to the first demonstration in a shorter amount of time

- With a high-quality product, you can get to market faster.

- Iterations can be done easily without the use of hardware.

- Capacity to handle more complex embedded systems has been improved.

- To boost development effectiveness, use disciplined research, design, and testing.

- Models that can be reused to reduce development time and costs.