Quality Assurance Foundation (Rules)

Quality Assurance and Testing Services Foundation (Rules) in the Embedded IIOT/IOT Domain

Background

The Internet of Things (IoT) is still in the speculation phase with customers, focused on IoT growth. Users are concerned, on the flip side, about liability and risk involved in IoT projects. Given this, it is necessary to address the IoT project assurance service line. Many factors contribute to the efficient execution of the IoT programs, and there are corresponding dimensions of assurance. In this article, we concentrate mainly on IoT testing.

Problem Statement

The top challenges & solutions that our experienced Quality Assurance team at Encoding Enhancers can enlist are as follows:

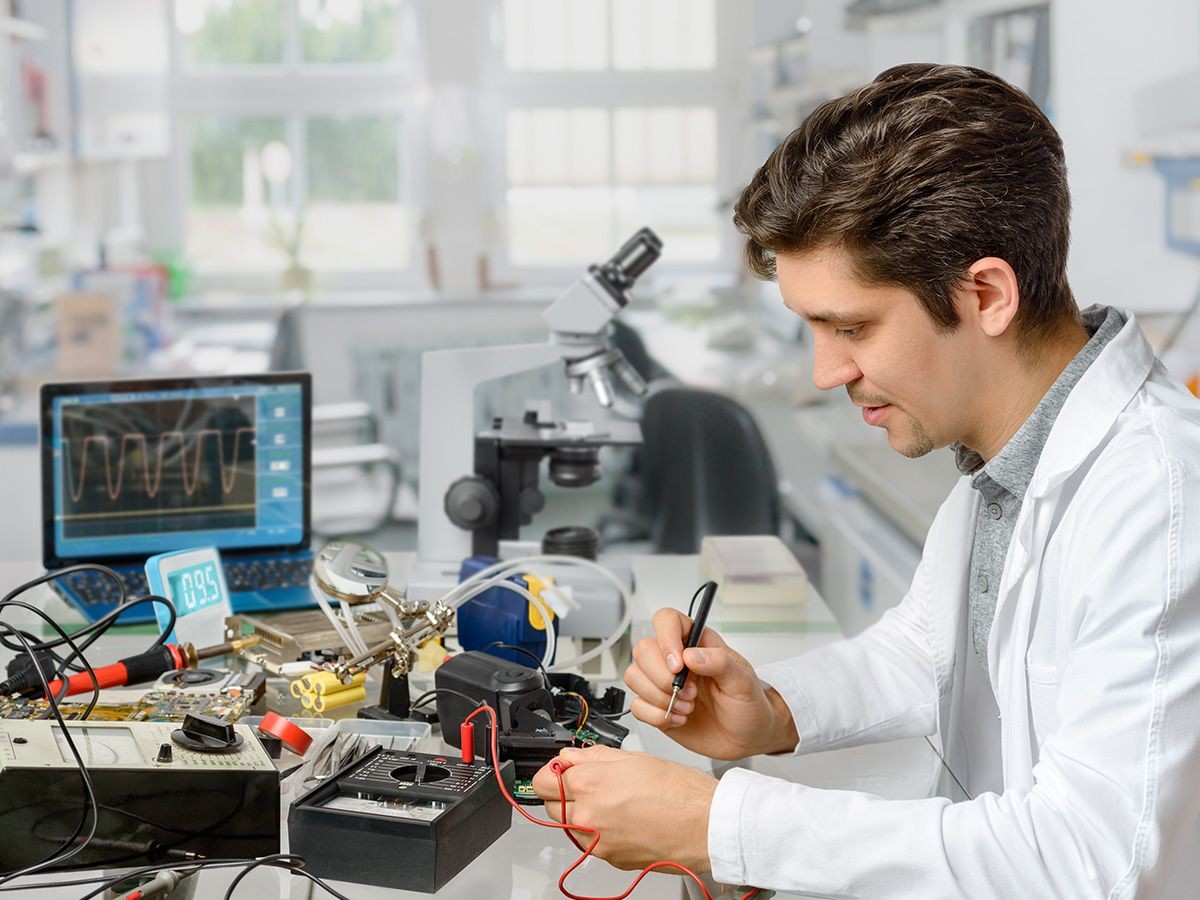

- Hardware & software convergence: The environment consists of computers, sensors & applications. Only validation of functionality is not adequate when it comes to millions of sensors in combination with intelligent apps.

- Additional reasons along with a working system: IoT operates with sensors & devices communicating with multiple software back-end with complex algorithms. To ensure a working collection of the device, the software is not enough. This requires a robust validation process with extremely complex real-time scenarios. Achieving such scenarios is an extreme challenge for the QA team.

- The device Interaction layer: Here the software & Hardware components interact in a real-time IoT environment. Additional challenges in addition to traditional software testing are their compliance to standards, interoperability, backward compatibility, and security.

- The user interface layer: The application\'s performance depends on the user\'s seamless experience. Simulation and system-level validation of network modes, real-time usability, and the IoT backend environment are the main challenges.

Solution

To counter the aforementioned challenges, Encoding Enhancers has worked for many industries namely heat trace for residential and commercial solutions

Take a heat tracing device example (Mainly used in Pipe freeze protection industrial & commercial areas) where a heat trace controller accepts temperature inputs and uses control algorithms to determine whether to turn off a heat trace. Useful data is recorded in the system and historical information can be viewed when appropriate. The heat monitoring circuit integrity is monitored and reported on constantly for temperatures, Earth leakage, operating currents, and other important data. This can be operated remotely from any of the devices to which the device is attached [computers or mobile devices].

We now need to take several IoT Test approaches to validate this architecture:

1. Usability:

- We need to make sure of the usability of each of the devices used here.

- The Industrial safety device (Heat tracing system, Leak detection system) used should be portable enough to be moved into different segments of the industries.

- The device should be smart enough to push not only notifications but also error messages, warnings, etc.

- The system should be able to log all events to provide the end-users with clarity. If this is not necessary, the system could push them to the database to store it.

- Notifications should be shown and proper handling of the display should be done in [computers / mobile devices] devices.

- The ability to view data, process data, and push work tasks from computers should be thoroughly tested.

2. IoT Security:

- IoT is a data-center that works based on available data for all connected devices and systems.

- As far as data flow is concerned, it is often possible to view or read the data when it is transferred.

- From a test point of view, we must analyze whether the data is secured/encrypted while switching from one device to another.

- We need to make sure that password protection exists wherever there is a UI.

3. Connectivity:

- Networking plays an important role in industrial safety solutions.

- The device must be continuously accessible and must be easily linked to the stakeholders.

- Two items are very critical for testing per connectivity;

4. Performance:

- We must ensure that the system is scalable enough for all remote areas if we are talking about an Industrial domain system.

- As testers, we need to make sure that the device performs the same thing even though the data added is propagated.

- We should also test the monitoring utility to demonstrate the use of the device, power consumption, temperature, etc.

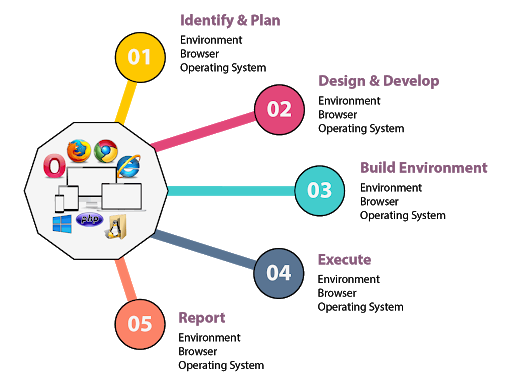

5. Compatibility Testing:

- Compatibility checking is a must if you look at the complex design of an IoT device.

- Test things such as different versions of the operating system, browser and version types, user generations, communication modes (e.g. For IoT compatibility testing, Bluetooth 2.0, 3.0] is required.

6. Upgrade testing:

- IoT is a mixture of several protocols, computers, operating systems, firmware, hardware, layers of networking, etc.

- In case of an upgrade as mentioned above, rigorous regression testing/strategy should be performed to overcome upgrade-related problems, regardless of device or other things involved.

Conclusions

The system/architecture involved can vary from the IoT testing approach. Instead of checking based on requirements, testers should focus more on testing as-a-Service [TAAS].

Integration testing is another significant player in IoT testing. If the Integration test plan is accurate and robust enough to detect device defects, IoT is successful.

It is also really exciting for the test team to certify such a complex mesh of devices, protocols, hardware, operating systems, firmware, etc., but IoT tests can be tough/challenging.

Encoding Enhancers is ISO 9001:2015 certified and provides comprehensive testing and quality assurance services across the entire product lifecycle, from requirement gathering to production testing. Backed by our in-depth technical expertise, we are the preferred partners for testing high-tech products and IoT solutions that extensively use multimedia, connectivity, and Imaging. Products we have productized have achieved very high DRE and very low DRR ratios.Encoding Enhancers also offers superlative test coverage and an accelerated time to market for our clients through test automation using in-house and open source tools. Test data and test suites developed in-house aide the complete testing process guaranteeing complete traceability.

To know more contact – sales@encodingenhancers.com or info@encodingenhancers.com