Digital Transformation in Manufacturing

Digital Transformation in Manufacturing

The digital environment is constantly changing for producers. The transformation is being propagated by the expected consumer change; devices linked to technological advances in neighboring industries in the sale of goods. We are already seeing the effects of digital transformation on the production it has on businesses, their suppliers, customers, and other third parties. This has many benefits, such as helping businesses adapt to changes quickly, or predicting changes before they happen - all of which are very important in production. Not surprisingly, in a few years, half of the producers will be invested in advanced consolidation and artificial intelligence to drive product development.

Top Digital Transformation Trends in Manufacturing

Industry 4.0

Industry 4.0 is a fashion that combines traditional production with industrial and digital industries. With the so-called "fourth industrial revolution", the main reason business is 4.0 is to make production processes a level where all strategies are computerized and managed in real-time. An example of this would be a sensor that communicates with another device primarily based on facts they discover, all of which happen without the intervention of another person. In the future, business 4.0 could blur the line of real and digital warehouses that can free employees with strong collaboration.

IOT

Other key business technologies 4.0 are (IOT), which is a community of highly communicative physical objects based on calculated records, environment, and exported records. This can create new features, offerings, and benefits for manufacturers. The most common conditions for IOT use, asset management, and personnel management. For example, manufacturers can develop block protection systems in real time, improve energy efficiency and operating conditions with intelligent air control, risk management, employee productivity, and more.

Machine learning

With the quantity of records machines are collecting, it’s less complicated than ever to make use of algorithms to quickly carry out the great path of motion among a couple of alternatives – something that might be too inefficient with human beings. These day's machines have established to us that exceptional isn't sacrificed for efficiency, as machines can more cautiously pick out and expect which factors will impact assembly line pace or fine. A few examples of system studying can include suggesting the best path of action for personnel, predict waiting times, delivery instances, or behavior fashions for danger prevention. Similarly, statistics generated by means of machines offer insights into all areas of the production manner whilst included throughout the delivery chain.

Robots

Future robots aren’t projected to vary plenty from what we see in manufacturing nowadays. What's going to alternate but is the gaining knowledge of things from preceding conduct and the usage of pattern popularity for improving effects. The range of linked gadgets, how they interact with every different, and the quantity of data are all expected to grow as well. Against the backdrop of connectivity, robots will keep innovating, specifically inside the areas of self-reliant driving, dexterous wearing, moving, and so on. And, with movement records being connected with its systems and groups across longer distances or even geographic locations, we are able to probably see this pressure quicker and greater powerful business choices.

B2B eCommerce

Today’s B2B eCommerce platforms must react to B2B buyer needs quickly, which tend to mirror those of B2C consumers. Preserving B2C-like experiences is difficult when B2Bs demand that custom checkout workflows, pricing rules, product data personalization, and other complex functions run in the background. Logistics applications are also there to improve logistics and ecommerce domain.

Benefits of Digital Transformation in Manufacturing

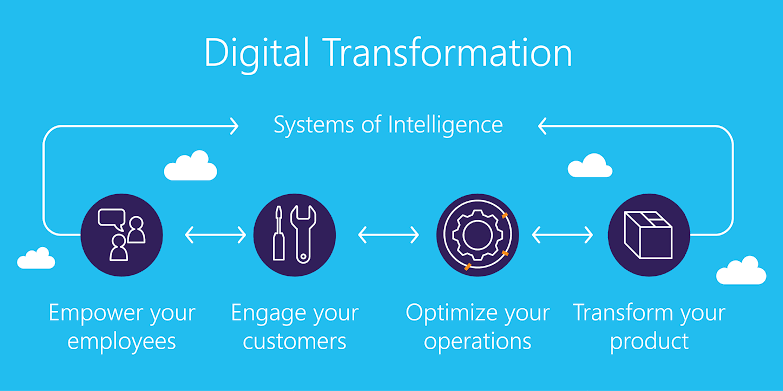

As virtual technology evolves all around us, manufacturers are more and more coming to crossroads: to convert and expand or stick with the tried, examined, and genuine techniques. Digital transformation offers many blessings in the long time, consisting of:

Higher Data Usage - Virtual transformation is ready optimizing records usage in operations, and manufacturers can utilize records more successfully – feeding it to their b2b ecommerce, ERP, CRP, finance, warehousing systems, and greater.

Improved processes - Virtual transformation has the possibility to revolutionize operations. As an instance, actual-time insights can help reveal, clear up or even expect situations that allows you to optimize equipment lifecycles. This allows keep errors-loose operation and avoid disruptions.

Increased Innovation - Innovation encourages innovation, so a digital transformation strategy unit the degree for a holistic technique to optimization. For instance, using smart manufacturing facility abilities in your ERP helps you enhance your commercial enterprise overall performance, as well as the supply chain, too.

Smarter Outsourcing – By introducing far off tracking, troubleshooting, proactive protection coupled with facts at their fingertips, manufacturers cannot best prevent disruptions, they can also put off risks of rushed solutions.

Purchaser Centricity - Manufacturers can get toward customers with the aid of launching a b2b ecommerce platform with separate portals for regions, manufacturers or clients. Moreover, producers can make use of sales statistics that correctly are expecting client demand and regulate their production consequently.

Conclusion

For the maximum component, virtual transformation tendencies in manufacturing goal customization and efficiency, agility and comparable regions. But any digital transformation method must by no means lose song of converting times. That’s why manufacturers need to constantly keep in mind that while digital transformation is inevitable, it needs to no longer be seen as an option to any unmarried region of manufacturing. Alternatively, developing a manufacturing virtual transformation roadmap must be checked out as an ongoing procedure of having and staying on the pinnacle of your marketplace.